Sunlight readable display solution

Sunlight readable display solution :

Optical bonding technology

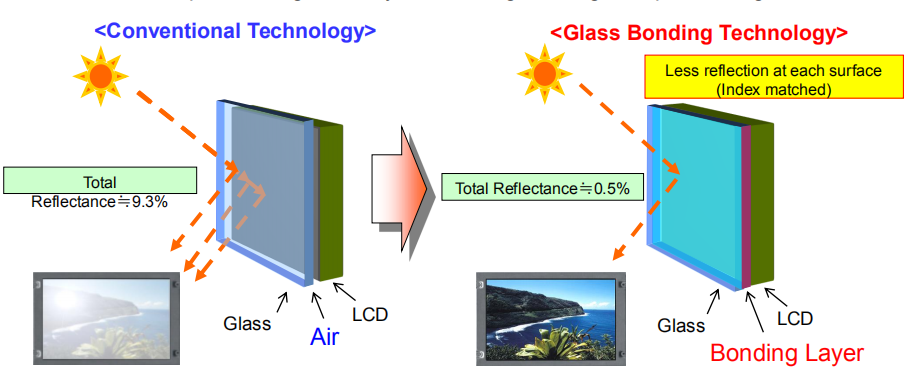

TFT LCD is the core of liquid crystal display. There is a polarizer on the front and back of the LCD panel. Especially the front polarizer is exposed to the outside. Due to the manufacturing process and material characteristics of the polarizer, it is generally not wear-resistant. It is easy to degumming and degeneration in case of moisture. It can't be used directly for outdoor display. The outdoor LCD screen needs to add a protective lens or touch screen. Ordinary screen glues the cover to the LCD screen, and an air layer is created in the middle, so that three reflective surfaces are formed from the outside to the inside, which are the surface of the touch screen, between the air and the touch screen, and the air and the touch screen. Two reflective surfaces are formed from the inside to the outside, which are the LCD screen to the air and the air to the back of the touch screen.

Principle of reflection under sunlight

There are three reflection surfaces from the outside to the inside, and the reflectivity of each reflection to the outside is about 4.2%, and the total reflection of external light is 12.6%, 1260 lumens.

If the screen surface brightness is 1000 lumens, each reflective surface loses 4.2%, and after two reflective surfaces passing from the inside to the outside, the brightness of the surface that penetrates the touch screen is 916 lumens.

The general ambient sunlight brightness is 10000 nit (cd/m2), assuming that the screen is a normal brightness IPS screen, the brightness is 400 nit, the contrast is 1000; the ambient light is from the outside to the inside of the three reflecting surfaces, and the reflectivity of each reflecting surface is substantially At 4.2%, the total external light is 12.6%, 1260 nit.

Since the brightness of the screen displayed on the screen is lower than the brightness of the reflected light, the reflected light makes the white brighter, submerging the black and other colors, so that the screen is poorly readable under strong light.

The brightness of the screen is 400 nit, and each reflecting surface is depleted by 4.2%. After the two reflecting surfaces passing through the inside and the outside, the brightness of the surface of the touch screen is 366 nit.

In bright light, the effective contrast of the screen is sharply reduced to 1.29, and ECR>5 can maintain good visibility in sunlight, so the screen generally does not clearly see the display under strong light reflection.

To improve the visibility of sunlight, in theory, we must start from the following aspects:

*Decreasing the brightness of reflected light, ie reducing the reflectivity;

*Reduce the surface reflectance of protective lenses or touch screens (LEEHON RAR/AG technology)

*Reduce the reflectivity of the air layer and the touch screen and display (LEEHON optical binding technology)

*Improve the brightness of the white field of the screen; (LEEHON high bright LCD display)

In order to increase the readability of the LCD screen under strong light, LEEHON has improved in the following aspects, greatly increasing the display optical effect and anti-vibration performance of the display, realizing the liquid crystal display to be clearly visible in sunlight, and enhanced Competitiveness in liquid crystal displays in high-end, outdoor and other fields.

High contrast

The use of optical bonding technology, the use of optical adhesive bonding, increase the utilization of backlight brightness, increase the brightness of LCM, can effectively reduce the specular reflectivity and increase the contrast of the display.

In order to solve the strong light reflection of the cover glass and the air layer, LEEHON introduced the surface AR technology.

One method is AR (Anti-reflective) technology: by coating one or more layers of ant0-ireflection coating on the outer surface of the glass, the reflected light on the surface of the glass can be reduced, and the anti-reflection film utilizes the optical interference effect of the thin layer, if a thin layer The thickness is exactly 1/4 of the wavelength of light (or an odd multiple of 1/4 wavelength), then the reflected light of the substrate is exactly half the wavelength of the reflected light on the surface of the thin layer. They destructively interfere with each other and cancel each other. (For the target wavelength), in order to achieve the broadband anti-reflection effect, multi-layer anti-reflection film optical matching technology is generally adopted.

Another method is the AG (Anti-Gray) technology: of course, an anti-Glare treatment for diffusing the reflected light can be performed on the surface of the glass, which is characterized in that the reflective surface of the original glass is changed to a matte diffuse reflective surface.

High brightness technology

Using LED instead of CCFL as backlight strip, with the help of LED backlight technology, not only improve the brightness of LCD, but also greatly improve the color reproduction and service life; plus optical film: brighten Polarizers and LCD panels with high light transmission can significantly increase the brightness of the LCD screen