skype:

skype:

In power control environments, an appropriate LCD screen serves not only as an information interface but also as a critical guarantee for stable system operation.

As the "nerve center" of power systems, the selection of LCD screens for power control cabinets directly impacts the monitoring efficiency and operational safety of the entire system. Unlike commercial or household displays, power control environments impose more stringent requirements on LCD screens.

This article systematically breaks down the key considerations for selecting LCD screens in power control cabinets, covering core factors, critical technical parameters, and practical application scenarios, to provide a comprehensive selection guide.

Power control cabinets are often installed in complex environments such as substations and distribution rooms. These scenarios pose multiple challenges for LCD screens, making it essential to prioritize the following special factors during selection.

Electromagnetic interference is a primary concern. Power control cabinets are typically located in strong electromagnetic environments like substations and distribution rooms. LCD screens must possess excellent interference resistance to prevent display abnormalities or data errors.

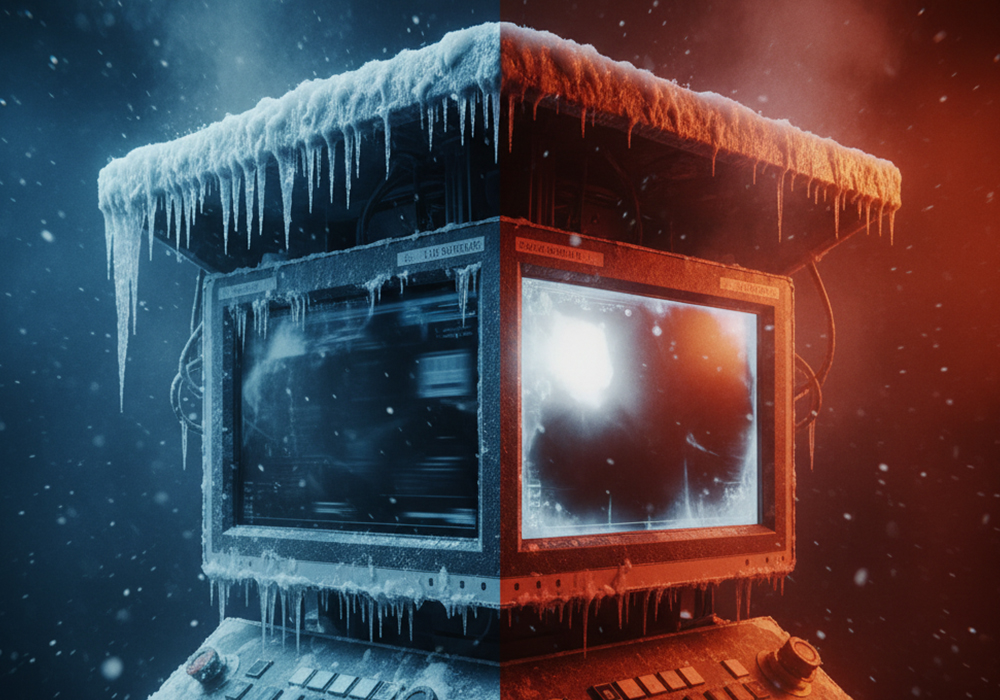

Extreme temperature fluctuations present another major challenge. Internal cabinet temperatures can soar above 70°C in summer and potentially drop as low as -40°C in outdoor winter installations. LCD screens need to operate reliably within this entire range.

Continuous operation requirements cannot be overlooked. Power monitoring systems require 24/7 uninterrupted operation. The backlight lifespan and overall reliability of the LCD screen directly impact the maintenance cycle of the entire system.

Additionally, stringent visibility requirements must be met. Control rooms may have high ambient light, and operators need to read displayed content clearly from various angles and under different lighting conditions.

Industrial-grade TFT LCD screens are the preferred choice for power control systems, offering full-color display, high resolution, and wide viewing angles. These features enable clear presentation of complex power system graphical interfaces.

Typically utilizing industrial-grade liquid crystal materials and driver chips, these screens support an extensive operating temperature range from -30°C to 80°C, meeting the demanding requirements of power control environments.

|

Environment Type |

Brightness |

Contrast Ratio |

Application Scenarios |

|

Indoor Control Cabinets |

250-400 nit |

≥800:1 |

Power distribution rooms, control centers |

|

Semi-Outdoor Environments |

250-400 nit |

≥1000:1 |

Outdoor cabinets, transition areas |

|

Fully Outdoor Environments |

≥1000 nit |

≥1500:1 |

Fully exposed environments |

Brightness selection requires striking a balance between visual requirements and power consumption. Excessively high brightness not only increases power consumption but also affects backlight lifespan.

Standard industrial LCDs :0℃ ~ +50℃

Wide-temperature LCDs:-30℃ ~ +80℃

Special wide-temperature LCDs:-40℃ ~ +85℃

For example, the G150XTN06.0 LCD can operate normally within a temperature range of -30°C to 85°C, matching the extreme temperature conditions that power control cabinets may encounter.

Power control cabinets typically utilize LCD screens ranging from 8.0 inches to 15.6 inches. Resolution should correspond appropriately to the size:

10.1-inch screen: 1280×800

15.6-inch screen: 1920×1080

Insufficient resolution will result in blurred display content, while excessively high resolution on similarly sized screens may make text and icons too small, impacting readability.

Industry or humid environments, it's essential to select industrial LCD screens with IP65/IP67 protection ratings.

IP65:Complete dust protection, protects against low-pressure water jets

IP67:Complete dust protection, can be briefly immersed in water

For most power control environments, an IP65 rating is generally sufficient.

Backlight Lifespan and Interface Types: Foundation for Long-Term Operation

Industrial LCD screens should have a backlight lifespan of ≥50,000 hours, with MTBF (Mean Time Between Failures) not less than 30,000 hours.

Interface selection is equally important:

LVDS interface:Strong anti-interference capability, long transmission distance, suitable for industrial environments.

eDP interface:High bandwidth, suitable for high-resolution displays.

VGA interface:Susceptible to interference in industrial environments - should be avoided where possible.

Resistive touchscreens operate through pressure sensing, supporting stylus and gloved operation. With strong impact resistance and lower cost, these screens feature plastic surfaces that offer good scratch resistance, making them suitable for frequently operated industrial applications.

In switchgear intelligent terminal solutions, pairing an 8.4-inch industrial LCD with an AMT 8.4-inch 4-wire resistive touchscreen represents a proven and reliable choice.

For internal HMI in control cabinets, industrial TFT LCD screens ranging from 8 inches to 12.1 inches with integrated touch functionality are typically recommended.

Recommended Model: BA104S01-300(ET104S0M-N16)

10.4-inch LCD display

800×600 resolution

350 cd/㎡ brightness (for indoor use)

Supports operating temperatures from -30℃ to 80℃

Specifically optimized for power control environments

For outdoor-installed control equipment, select high-brightness, wide-temperature LCD screens with:

Brightness not less than 700 cd/㎡

Operating temperature range: -40℃ to 85℃

Integrated automatic brightness adjustment function

Recommended protection rating: IP65 or higher

For mobile monitoring terminals or portable power detection devices, choose LCD screens that feature:

Wide-temperature operation and strong shock resistance

Support for wide power supply voltage ranges (e.g., 9-36V)

Compatibility with special environments like vehicle vibration

Compact sizes (typically 8 inches or smaller)

LCD screens for power control systems must comply with relevant industry standards, which serve as fundamental selection criteria:

EMC Standards : Meets the IEC 61000-4 series of electromagnetic compatibility standards, ensuring stable operation in high-electromagnetic interference environments.

Safety Standards : Complies with IEC 62368-1 information technology equipment safety standards, guaranteeing operator safety.

Environmental Adaptability: Satisfies the IEC 60068-2 series of environmental testing standards, including vibration, shock, and temperature cycling tests.

Power Industry Standards: Adheres to power automation communication standards such as DL/T 860 (IEC 61850), ensuring seamless integration with power systems.

Step 1: Requirements Analysis

Define fundamental requirements including:

Environmental temperature range

Electromagnetic interference intensity

Viewing distance and angles

Operation frequency and methods

Step 2: Technical Parameter Specification

Establish preliminary technical specifications by determining key parameters such as:

Dimensions

Resolution

Brightness levels

Step 3: Supplier Evaluation

Select reliable suppliers (LEEHON)with power industry experience, assessing:

Product quality consistency

Supply lead times

Technical support capabilities

Industry reputation and case studies

Step 4: Sample Testing

Conduct comprehensive validation testing in real-world conditions:

High/low-temperature tests

Vibration resistance tests

EMC compliance tests

Accelerated lifespan testing

Step 5: Pilot Implementation

Initiate small-scale trial deployments before full procurement to:

Verify stable performance

Mitigate project risks

Over-Pursuit of High Specifications

Avoid blindly chasing the highest specifications - the most suitable solution is the optimal choice. For instance, 400 nits brightness consumes 37% less power annually compared to 700 nits. Large-scale deployments require careful evaluation of the balance between actual needs and energy consumption.

Neglecting Interface Compatibility

Ensure LCD interface compatibility with existing control systems. Incompatible interfaces necessitate additional conversion equipment, increasing both costs and potential failure points.

Overlooking Installation Structure

Consider mounting methods and heat dissipation requirements in advance to ensure compatibility with control cabinet structures. Improper installation can compromise thermal management, ultimately affecting lifespan and stability.

Underestimating Supply Lead Times

Industrial-grade LCD screens may have extended supply cycles. Proactive procurement planning is essential to prevent project schedule impacts.

Opt for modular-designed LCD screens to facilitate future maintenance and replacement.

Verify suppliers can provide long-term technical support and spare parts availability.

Consider backlight module replaceability - replacing faded backlights restores performance, extends overall service life, and reduces total cost of ownership.

In selecting LCD screens for power control cabinets, there's no "best" product, only the "most appropriate" solution. Wide-temperature performance, extended lifespan, and high reliability represent core requirements for power control environments. Scientific selection methodologies and systematic evaluation processes ensure optimal solution identification.

A well-chosen LCD screen serves not merely as a display component, but as a critical safeguard for stable power control system operation. Through systematic selection approaches that balance technical parameters, environmental factors, and cost considerations, you can identify the ideal display solution that ensures safe, stable, and efficient power system operation.

If you are interested in our industrial LCD screens or want to learn more about how to choose the most suitable brightness parameters based on your specific applications, we welcome you to contact us at any time. Our expert team will provide you with professional consultation and support to help you find the most suitable industrial display solution for your needs.

Please contact us through the following methods to start your journey to a customized solution:

Visit our official website: [www.lhlcdpanel.com]

Send an email to: [celia@leehon.com]

Call us at: [0086-15906639973]

We look forward to working with you to bring you greater value.